Project Description

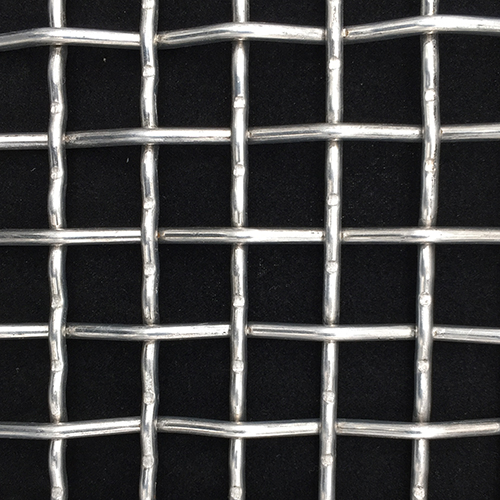

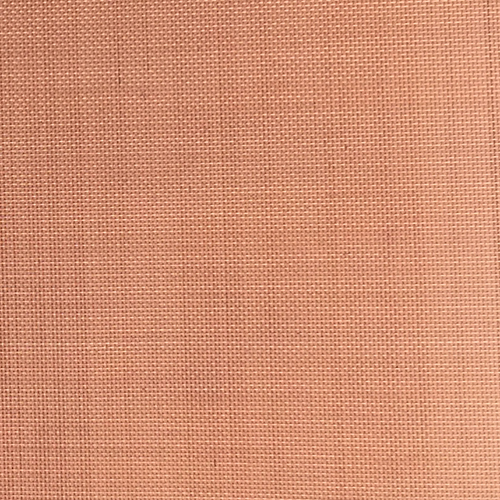

Dutch Weave Wire Mesh is also known as stainless steel dutch woven wire cloth and stainless steel filter cloth. It is usually made of mild steel wire and stainless steel wire.Stainless steel dutch wire mesh is extensively utilized as filter fittings for chemical industry, medicine, petroleum, scientific research units ,due to its stable and fine filtration capability.

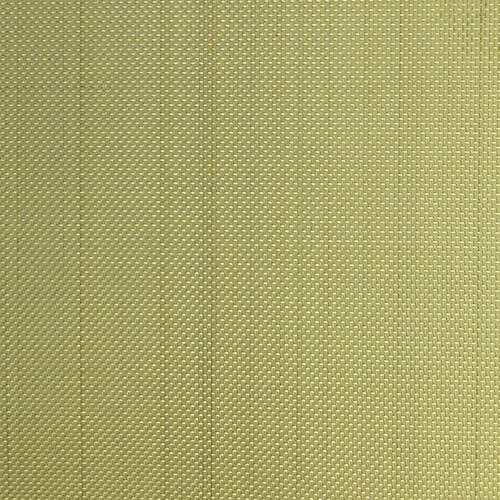

The apparent difference of reverse dutch weaving compared with standard dutch weave lies in the thicker warp wires and less weft wires. Reverse dutch woven stainless steel wire cloth offers finer filtration and finds popular application in petroleum, chemical, food, pharmacy and other fields.Through constant technological innovation and improvement, we can produce stainless steel wire mesh of various specification in reverse Dutch weaving patterns.

Product Feature:

Properties of dutch wire mesh filtration,fine stability,high precision,with special filtration performance.

Product Description:

Dutch wire mesh is made of high quality stainless steel wire woven.The main feature is the warp and weft wire diameter and density of greater contrast, and therefore the net thickness and filtering accuracy and life will have a more significant increase than the average square mesh.

Specification:

1, Available Material: Stainless steel SUS304, SUS304L, SUS316, SUS316L, copper, nickel, monel, titanium, silver, plain steel, galvanized iron, aluminum and etc.

2, Size: Up to clients

3, Pattern design: up to clients, and we can offer suggestion as well based on our experience.

Product Application:

Widely used precision pressure filters,the fuel filter,vacuum filter, as filter materials,aerospace, pharmaceutical, sugaring, oil, chemical, chemical fiber, rubber, tire manufacturing, metallurgy, food, health research,etc industries.

Advantage:

1, Adopt high quality stainless steel, SUS304, SUS316, and etc. To ensure the high quality of the end products.

2, Strictly follow worldwide advanced technical standard to produce all of our products.

3, High degree corrosion, excellent oxidation resistance, can be used for a long term.

Common Specifications of Plain Dutch Weave Wire Mesh

| Mesh(warp×weft) | Wire Dia. (mm) | Opening (um) | Weight (kg/sq.m) |

|---|---|---|---|

| 7 x 44 | 0.71×0.63 | 315 | 5.42 |

| 12×64 | 0.56×0.40 | 211 | 3.89 |

| 12×76 | 0.45×0.35 | 192 | 3.26 |

| 10×90 | 0.45×0.28 | 249 | 2.57 |

| 8 x 62 | 0.63×0.45 | 300 | 4.04 |

| 10 x 79 | 0.50×0.335 | 250 | 3.16 |

| 8 x 85 | 0.45×0.315 | 275 | 2.73 |

| 12 x 89 | 0.45×0.315 | 212 | 2.86 |

| 14×88 | 0.50×0.30 | 198 | 2.85 |

| 14 x 100 | 0.40×0.28 | 180 | 2.56 |

| 14×110 | 0.0.35×0.25 | 177 | 2.28 |

| 16 x 100 | 0.40×0.28 | 160 | 2.64 |

| 16×120 | 0.28×0.224 | 145 | 1.97 |

| 17 x 125 | 0.35×0.25 | 160 | 2.14 |

| 18 x 112 | 0.35×0.25 | 140 | 2.37 |

| 20 x 140 | 0.315×0.20 | 133 | 1.97 |

| 20 x110 | 0.35 x 0.25 | 125 | 2.47 |

| 20×160 | 0.25×0.16 | 130 | 1.56 |

| 22 x 120 | 0.315×0.224 | 112 | 2.13 |

| 24 x 110 | 0.35×0.25 | 97 | 2.6 |

| 25 x 140 | 0.28×0.20 | 100 | 1.92 |

| 30 x 150 | 0.25×0.18 | 80 | 2.64 |

| 35 x 175 | 0.224×0.16 | 71 | 1.58 |

| 40 x 200 | 0.20×0.14 | 60 | 1.4 |

| 45 x 250 | 0.16×0.112 | 56 | 1.09 |

| 50 x 250 | 0.14×0.10 | 50 | 0.96 |

| 50×280 | 0.16×0.09 | 55 | 0.98 |

| 60 x 270 | 0.14×0.10 | 39 | 1.03 |

| 67 x 310 | 0.125×0.09 | 36 | 0.9 |

| 70 x 350 | 0.112×0.08 | 36 | 0.79 |

| 70 x 390 | 0.112×0.071 | 40 | 0.72 |

| 80×400 | 0.125×0.063 | 32 | 0.77 |

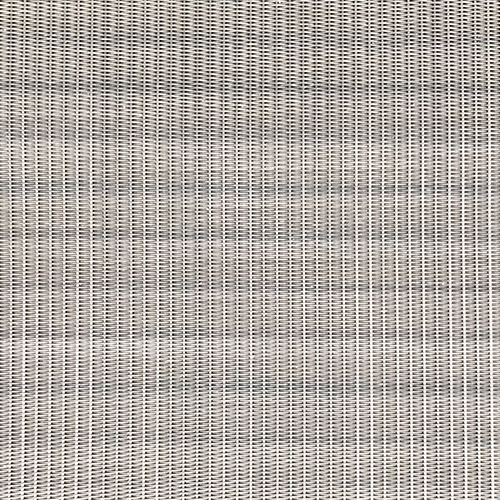

Common Specifications of Twill Dutch Weave Wire Mesh

| Mesh(warp×weft) | Wire Dia. (mm) | Opening (um) | Weight (kg/sq.m) |

|---|---|---|---|

| 20×200 | 0.355×0.28 | 118 | 4.58 |

| 20×260 | 0.25×0.20 | 119 | 3.14 |

| 24×300 | 0.28×0.18 | 110 | 3.01 |

| 30×250 | 0.28×0.20 | 77 | 3.41 |

| 30×340 | 0.28×0.16 | 89 | 2.84 |

| 40×560 | 0.18×0.10 | 70 | 1.73 |

| 80 x 700 | 0.112 x 0.08 | 30 | 1.39 |

| 80 x 790 | 0.112 x 0.071 | 32 | 1.26 |

| 80 x 790 | 0.10 x 0.071 | 30 | 1.22 |

| 90 x 760 | 0.10 x 0.071 | 25 | 1.24 |

| 100 x 850 | 0.10 x 0.063 | 28 | 1.12 |

| 100 x 850 | 0.10 x 0.063 | 22 | 1.15 |

| 100 x 760 | 0.10 x 0.071 | 20 | 1.26 |

| 130 x 1100 | 0.071 x 0.050 | 17 | 0.88 |

| 150 x 1400 | 0.063 x 0.040 | 16 | 0.72 |

| 160 x 1500 | 0.063 x 0.040 | 15 | 0.67 |

| 165 x 1400 | 0.063 x 0.04 | 13 | 0.73 |

| 165 x 1500 | 0.063 x 0.036 | 14 | 0.68 |

| 174 x 1400 | 0.063 x 0.040 | 11 | 0.74 |

| 174 x 1700 | 0.063 x 0.032 | 13 | 0.63 |

| 203 x 1600 | 0.050 x 0.032 | 10 | 0.58 |

| 250×1600 | 0.05×0.032 | 8 | 0.63 |

| 250 x 1900 | 0.040 x 0.028 | 8 | 0.5 |

| 247 x 2235 | 0.040 x 0.025 | 9 | 0.45 |

| 280 x 2200 | 0.036 x 0.025 | 7 | 0.45 |

| 300 x 2200 | 0.036 x 0.025 | 4 | 0.44 |

| 325×2300 | 0.036×0.025 | 4 | 0.46 |

| 400 x2700 | 0.028 x 0.02 | 4 | 0.36 |

Common Specifications of Reverse Dutch Weave Wire Mesh

| Mesh(warp×weft) | Wire Dia. (mm) | Opening (um) | Weight (kg/sq.m) |

|---|---|---|---|

| 63 x 18 | 0.40 x 0.60 | 210-230 | 4.21 |

| 107 x 20 | 0.24 x 0.60 | 210 | 3.38 |

| 170x 40 | 0.20 x 0.45 | 130 | 2.74 |

| 132×32 | 0.20 x 0.40 | 105 | 2.69 |

| 171 x 46 | 0.15 x 0.30 | 85 | 2.05 |

| 290×75 | 0.09 x 0.20 | 38-45 | 1.27 |

| 615×102 | 0.040x 0.16 | 40-48 | 0.92 |

| 625×135 | 0.04 x 0.13 | 18-23 | 0.85 |

| 720×150 | 0.035 x 0.10 | 16-20 | 0.6 |