Woven wire mesh is a highly durable and versatile material widely used in industrial applications. From filtration and protection to structural support, woven wire mesh has proven invaluable in a variety of sectors. In this article, we delve into the key benefits of woven wire mesh and explore its applications across major industries, helping you understand how to select the right mesh for your industrial needs.

What is Woven Wire Mesh?

Types of Woven Wire Mesh

Woven wire mesh is made by weaving metal wires in patterns that vary in density, thickness, and weave style. Common types include plain weave, twill weave, and Dutch weave, each offering different strengths and characteristics suited for specific applications.

Materials Commonly Used in Industrial Mesh

For industrial applications, woven wire mesh is often made from stainless steel, galvanized steel, or aluminum. Stainless steel is especially popular for its corrosion resistance and durability, while aluminum is prized for its lightweight and flexible properties.

Key Benefits of Woven Wire Mesh in Industrial Settings

Durability and Resistance to Corrosion

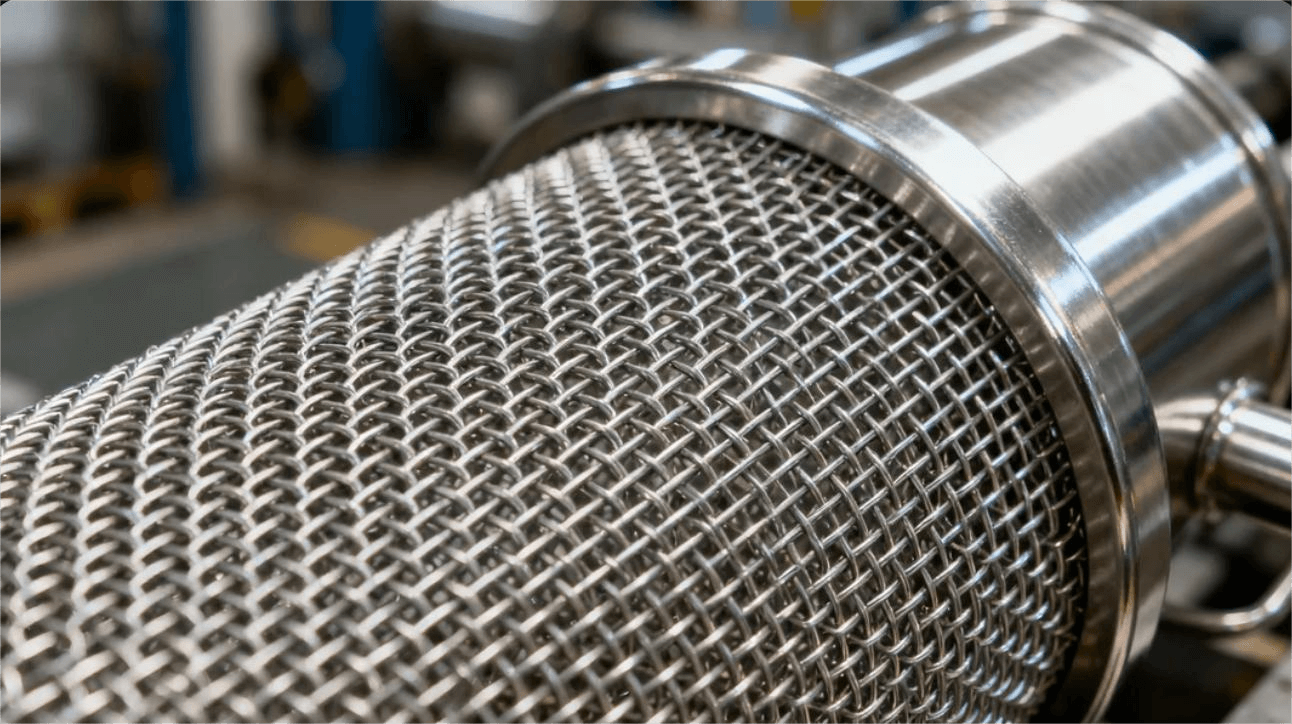

One of the primary benefits of woven wire mesh is its durability, especially in harsh industrial environments. Stainless steel woven wire mesh, in particular, offers excellent resistance to corrosion, making it suitable for industries like chemical processing and wastewater treatment.

Flexibility and Customization

Woven wire mesh can be customized to meet the specific needs of industrial applications. It is available in various mesh sizes, materials, and weave patterns, allowing it to be tailored for everything from filtration systems to protective barriers.

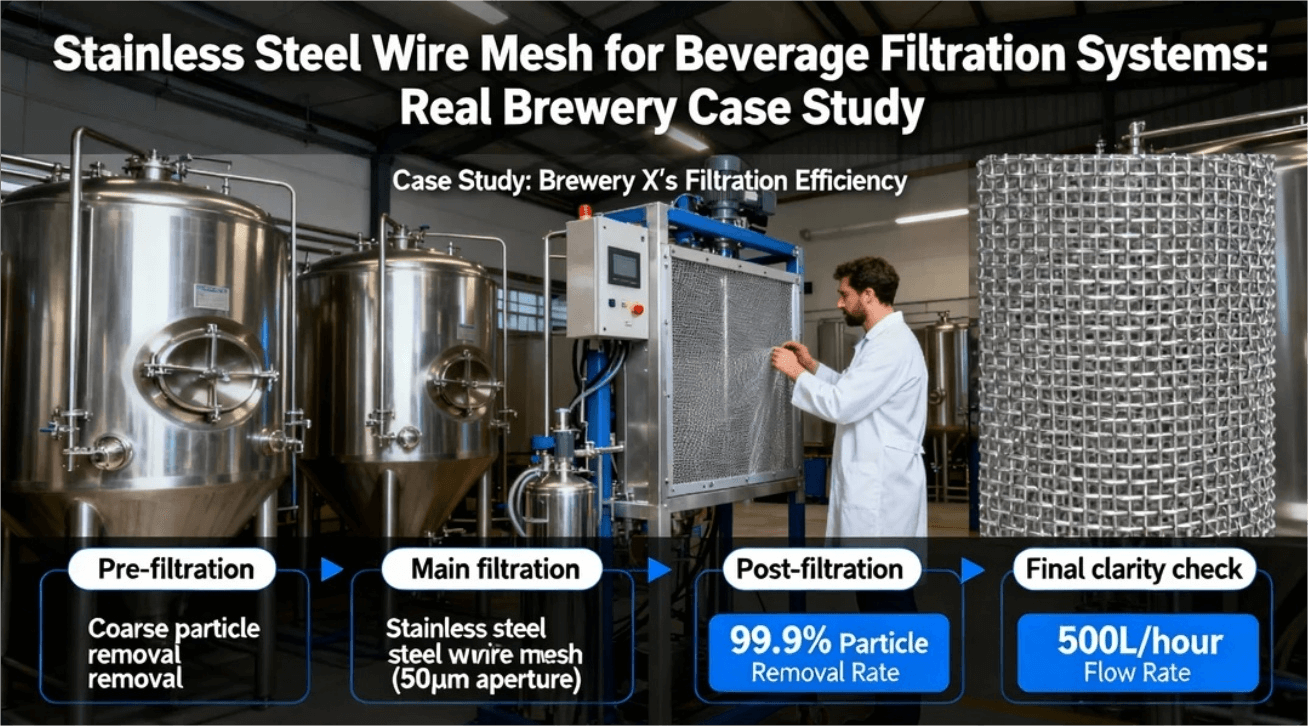

High Precision for Filtration

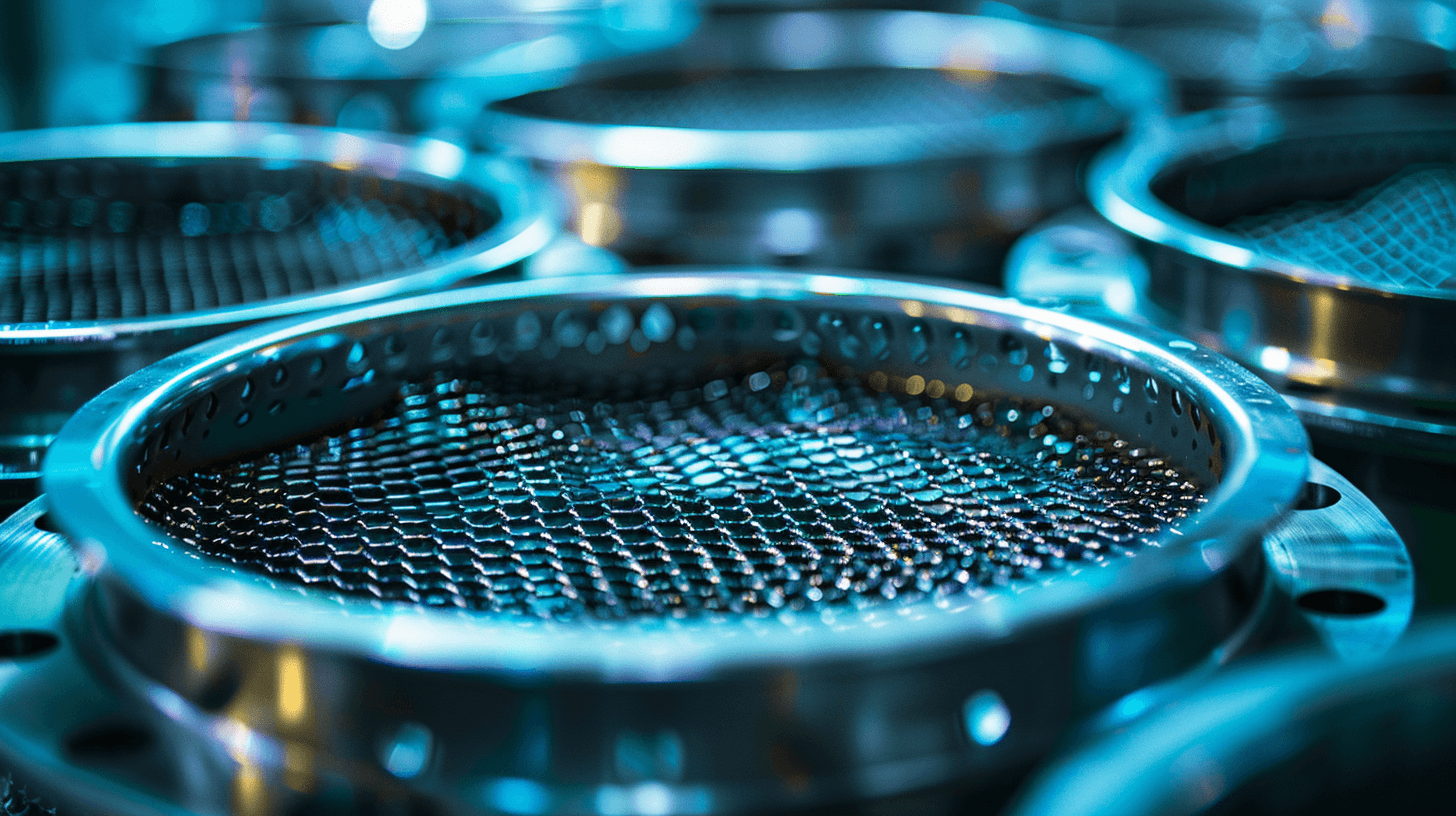

In filtration applications, precision is essential, and woven wire mesh delivers high accuracy in separating particles. Its consistent, uniform openings enable it to effectively filter liquids and gases, making it a reliable choice for industries requiring fine filtration.

Top Industrial Applications of Woven Wire Mesh

Filtration in the Chemical and Oil Industries

Woven wire mesh is commonly used for filtration in the chemical and oil industries, where it helps to separate contaminants from liquids and gases. Its durability and precision make it an ideal choice for these demanding applications.

Protective Screens in Manufacturing and Construction

In manufacturing and construction, woven wire mesh is used as a protective screen to safeguard workers and machinery from debris. It is also utilized in safety barriers and enclosure panels due to its strength and visibility, ensuring both protection and a clear line of sight.

Structural Support in Mining and Aggregate Processing

For heavy-duty applications in mining and aggregate processing, woven wire mesh provides crucial structural support. It is used in screening and sorting operations, where its durability ensures reliable performance under heavy loads.

How to Choose the Right Woven Wire Mesh for Industrial Use

Choosing the Right Mesh Size

Selecting the appropriate mesh size is critical for ensuring optimal performance in industrial applications. A smaller mesh size is typically required for fine filtration, while a larger mesh size may be suitable for protective screens or structural applications.

Material Selection Based on Application

The choice of material for woven wire mesh depends on the application. For environments exposed to moisture or corrosive substances, stainless steel is preferred, whereas aluminum might be chosen for applications that prioritize lightweight materials.

Evaluating Weave Patterns for Performance Needs

Different weave patterns impact the performance of woven wire mesh. For instance, plain weave offers a uniform opening size, while Dutch weave is suitable for high-pressure filtration due to its tighter weave and strength.

Conclusion

Woven wire mesh is a valuable asset across various industries, thanks to its durability, precision, and adaptability. Whether used for filtration, protection, or structural support, understanding the benefits and applications of woven wire mesh can help you choose the best solution for your industrial needs. For more information on our woven wire mesh products and how they can benefit your operations, contact our experts today.