Stainless steel wire mesh filters are essential components in various industrial and commercial applications. Their durability, efficiency, and versatility make them a preferred choice for many filtration needs. This guide will delve into what stainless steel wire mesh filters are, their key benefits, common applications, and how to choose the right filter for your specific requirements.

—

What is a Stainless Steel Wire Mesh Filter?

Definition and Structure

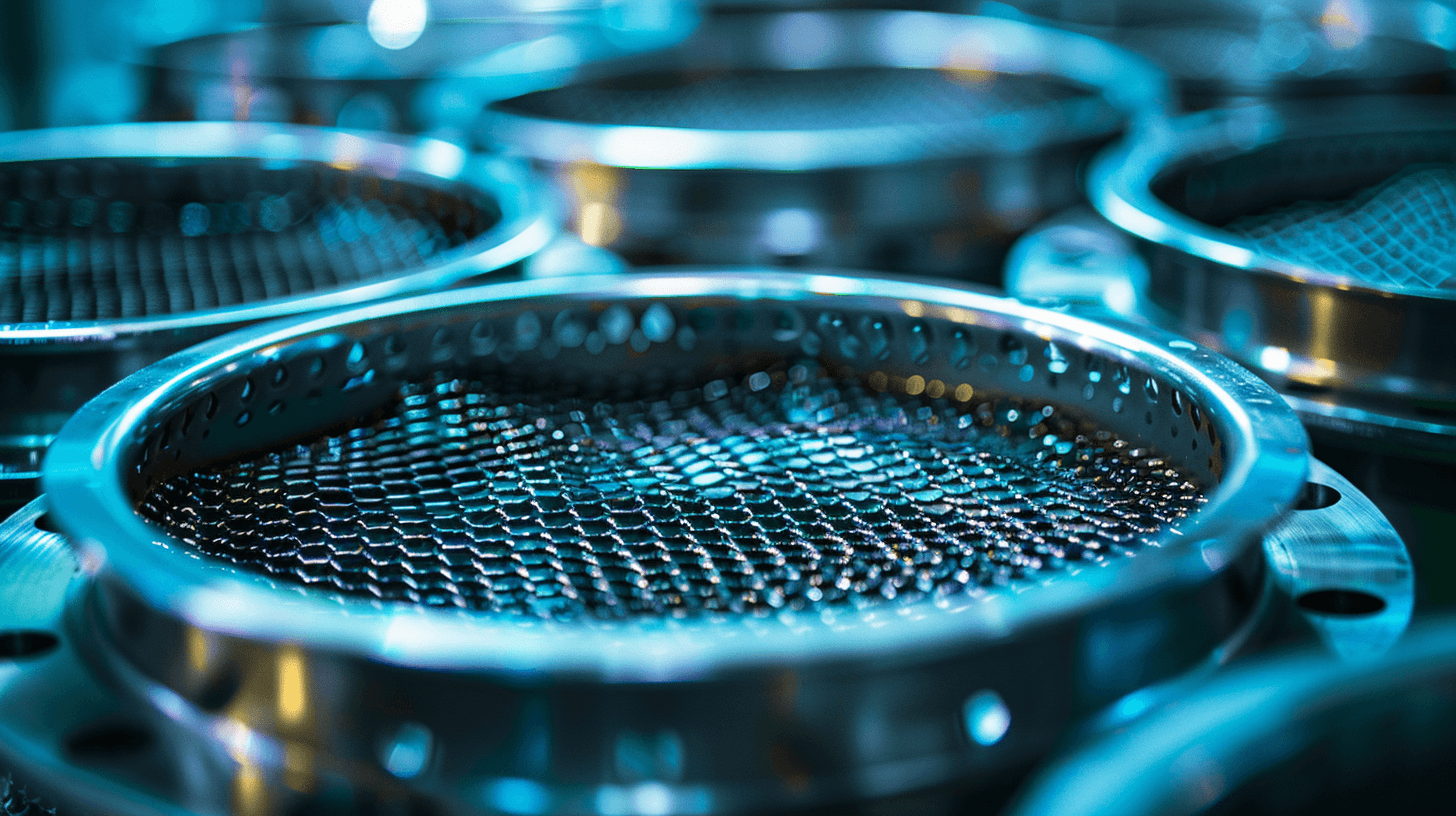

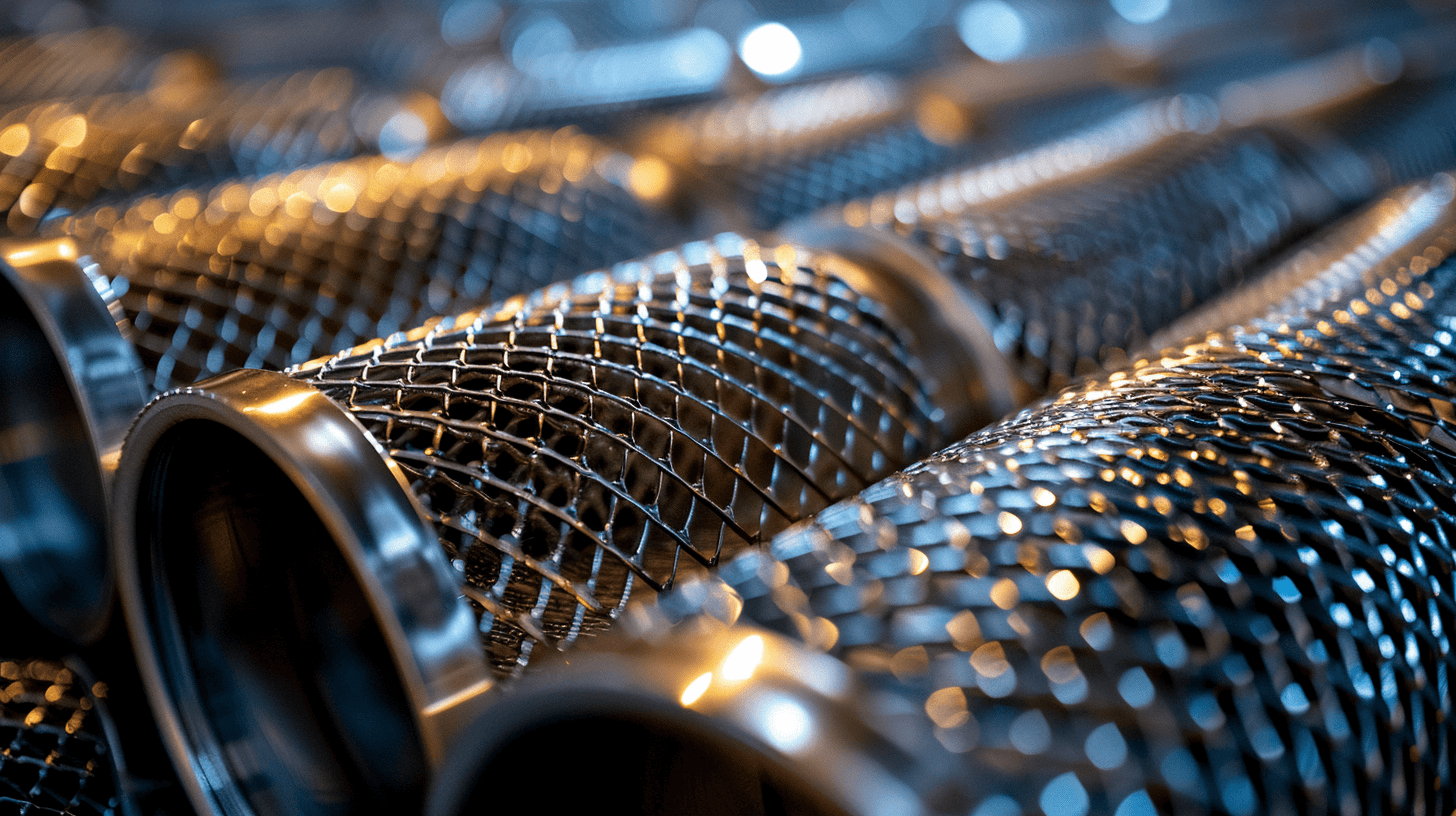

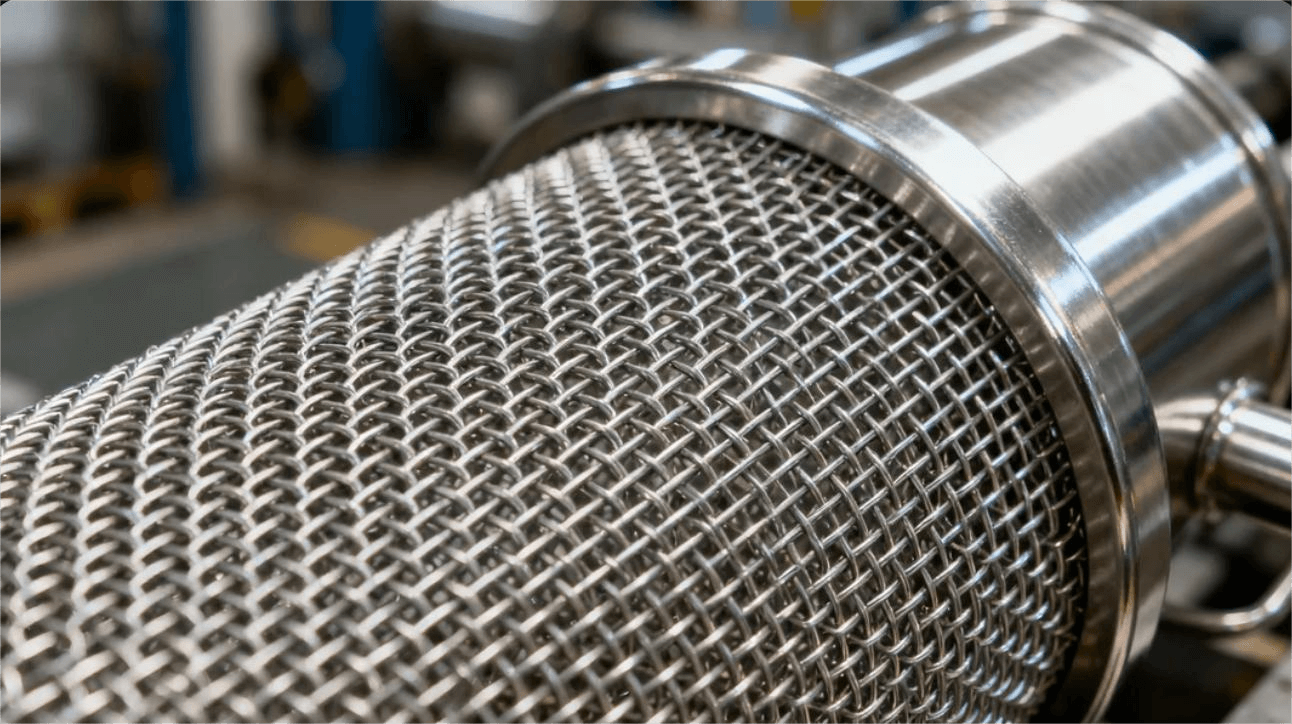

A stainless steel wire mesh filter consists of interwoven stainless steel wires forming a mesh with precise openings. These openings can vary in size, allowing the filter to trap particles of different sizes while allowing fluids or gases to pass through.

Types of Stainless Steel Wire Mesh Filters

There are several types of stainless steel wire mesh filters, including:

– Plain Weave Filters: Simple over-and-under weave providing uniform openings.

– Twill Weave Filters: Offers a higher level of strength and durability.

– Dutch Weave Filters: Combines finer mesh with heavier wire, ideal for high-pressure applications.

Key Benefits of Using Stainless Steel Wire Mesh Filters

Durability and Longevity

Stainless steel wire mesh filters are known for their exceptional durability. They can withstand high temperatures, pressures, and harsh chemicals, making them suitable for demanding environments.

High Filtration Efficiency

These filters provide high filtration efficiency due to their precise mesh openings, ensuring effective removal of contaminants from fluids and gases.

Corrosion Resistance

The corrosion-resistant properties of stainless steel make these filters ideal for applications involving exposure to moisture, chemicals, and other corrosive elements.

Versatility in Application

Stainless steel wire mesh filters are versatile and can be used in a wide range of applications, from industrial filtration systems to household water purification.

—

H2: Common Applications of Stainless Steel Wire Mesh Filters

H3: Industrial Filtration Systems

In industrial settings, stainless steel wire mesh filters are used to remove impurities from liquids and gases, ensuring the smooth operation of machinery and equipment.

Water Treatment Plants

These filters are essential in water treatment plants for removing contaminants from water, ensuring it meets safety and quality standards.

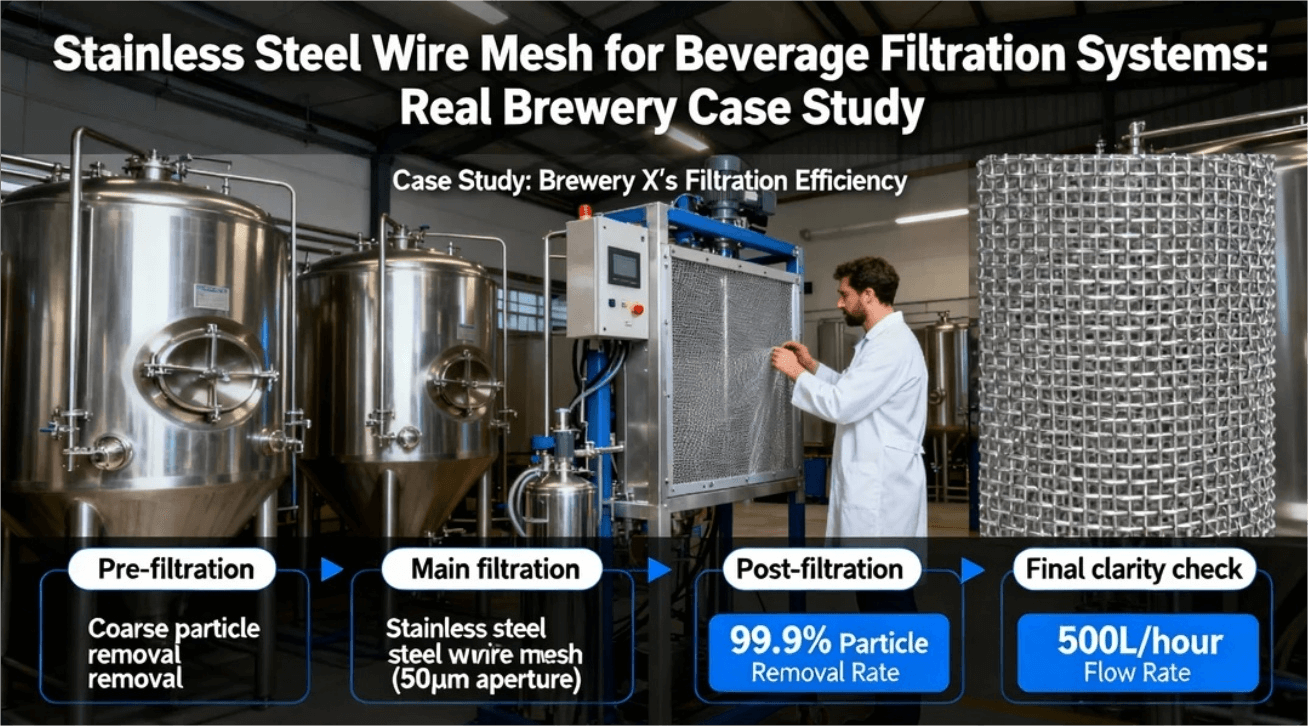

Food and Beverage Processing

Stainless steel wire mesh filters are used in the food and beverage industry to ensure products are free from impurities, maintaining high standards of hygiene and safety.

Pharmaceutical Manufacturing

In pharmaceutical manufacturing, these filters play a critical role in maintaining the purity of products, preventing contamination, and ensuring compliance with stringent industry regulations.

—

How to Choose the Right Stainless Steel Wire Mesh Filter

H3: Mesh Size and Micron Rating

Selecting the right mesh size and micron rating is crucial for the filter’s efficiency. The mesh size determines the size of particles that can be filtered out, while the micron rating indicates the filter’s precision.

Material Grade and Weave Type

Different grades of stainless steel and weave types offer varying levels of strength and durability. Choose a material grade and weave type that suits your application’s specific needs.

Application-Specific Considerations

Consider factors such as the operating environment, temperature, pressure, and the nature of the contaminants when selecting a stainless steel wire mesh filter for your application.

—

Conclusion

Stainless steel wire mesh filters are indispensable in many industries due to their durability, efficiency, and versatility. By understanding their benefits and applications, you can make informed decisions about the right filter for your needs. For more information on our stainless steel wire mesh filter products and how they can enhance your operations, contact us today.