Stainless steel woven wire mesh has become a top choice for filtration applications due to its strength, durability, and precision. Whether filtering liquids, gases, or particles, stainless steel mesh provides a reliable and efficient solution across many industries. In this article, we’ll explore why stainless steel woven wire mesh stands out as the ideal material for filtration and how to select the right one for your specific needs.

What is Stainless Steel Woven Wire Mesh?

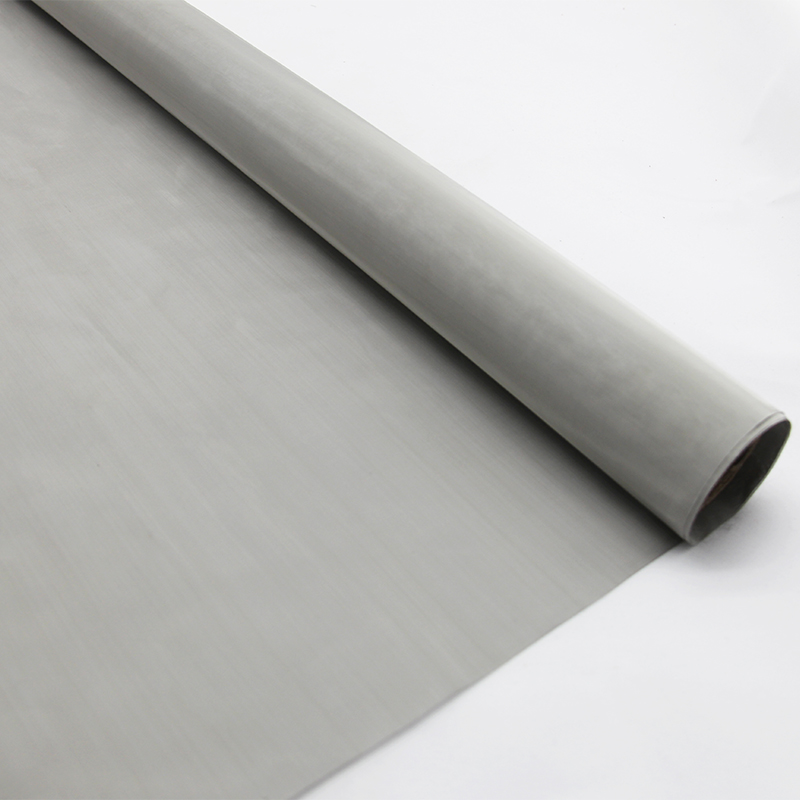

How It’s Made

Stainless steel woven wire mesh is produced by weaving stainless steel wires together to form a uniform pattern. This weaving process can create a variety of mesh types, such as plain weave, twill weave, or Dutch weave, each offering different benefits depending on the application.

Material Grades Used in Filtration

Stainless steel grades commonly used for filtration applications include 304, 316, and 316L. These grades are known for their excellent resistance to corrosion and high temperatures, making them suitable for demanding environments.

Key Benefits of Using Stainless Steel Woven Wire Mesh for Filtration

Durability in Harsh Conditions

One of the key benefits of stainless steel woven wire mesh is its durability. It can withstand extreme temperatures, pressure, and exposure to chemicals, ensuring long-term performance in industrial filtration systems.

Precision and Efficiency in Filtration

Stainless steel mesh is known for its precision. With accurate and consistent pore sizes, it ensures efficient separation of particles, making it ideal for applications requiring fine filtration.

Corrosion and Heat Resistance

Stainless steel’s resistance to rust and corrosion is another major advantage, especially in environments where filters are exposed to moisture or corrosive substances. Additionally, it performs well in high-temperature filtration, maintaining its structural integrity and performance.

Common Filtration Applications for Stainless Steel Woven Wire Mesh

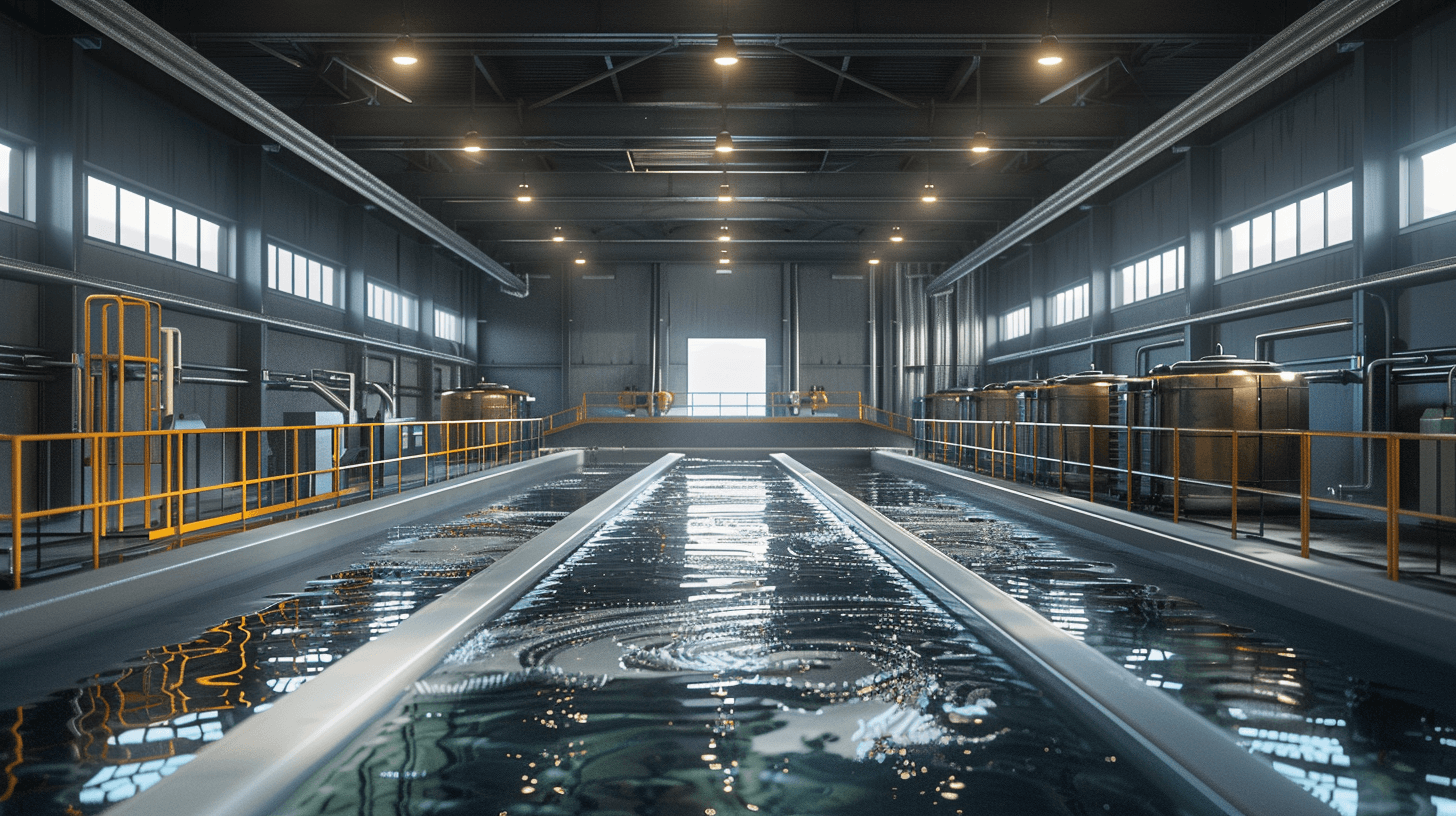

Liquid Filtration

Stainless steel woven wire mesh is widely used in liquid filtration systems, such as water treatment, chemical processing, and oil filtration. Its fine mesh count enables it to effectively remove contaminants from liquids without clogging.

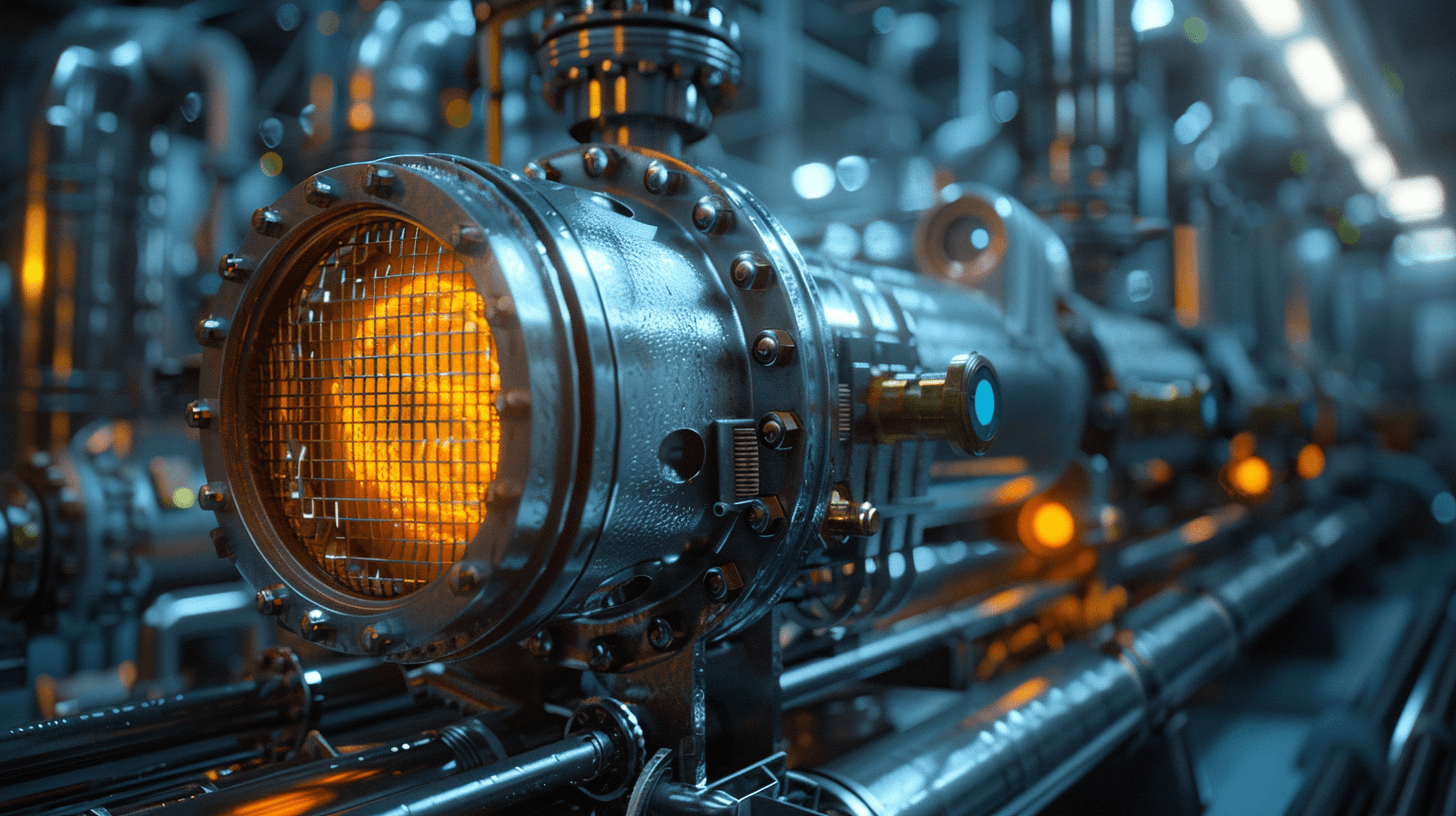

Gas Filtration

In industries like aerospace and automotive, stainless steel mesh is crucial for gas filtration. It helps in filtering out impurities from air, fuel, and exhaust gases, improving system efficiency and reducing emissions.

Industrial and Commercial Filtration

From pharmaceutical production to food and beverage processing, stainless steel mesh is favored for its sanitary properties and compliance with strict regulatory standards. Its non-reactive nature makes it safe for use in sensitive environments.

How to Select the Right Stainless Steel Woven Wire Mesh for Your Needs

Mesh Count and Filtration Efficiency

The mesh count, which refers to the number of wires per inch, determines the mesh’s filtration efficiency. A higher mesh count means smaller openings, making it ideal for fine filtration, while lower mesh counts are better suited for larger particles.

Wire Diameter and Strength

Choosing the right wire diameter is essential for ensuring that the mesh can handle the pressure and stress of filtration without breaking. Thicker wires offer more strength but may reduce the flexibility of the mesh.

Choosing the Right Weave Pattern

The weave pattern can significantly impact filtration performance. For example, plain weave is suitable for most applications, while Dutch weave provides tighter filtration for ultra-fine particles.

Conclusion

Stainless steel woven wire mesh is unmatched in its performance and versatility in filtration applications. Its durability, precision, and resistance to corrosion and heat make it a reliable solution for industries requiring high-performance filtration. If you’re looking for the right stainless steel wire mesh for your filtration system, contact our experts today to learn more about the best options for your specific needs.