Woven wire mesh is an essential component in various industrial filtration processes. Known for its precision and durability, it offers numerous advantages in ensuring efficient and reliable filtration. In this article, we will explore the benefits and applications of woven wire mesh in industrial filtration, helping you choose the right mesh for your specific needs.

—

What is Woven Wire Mesh?

Definition and Structure

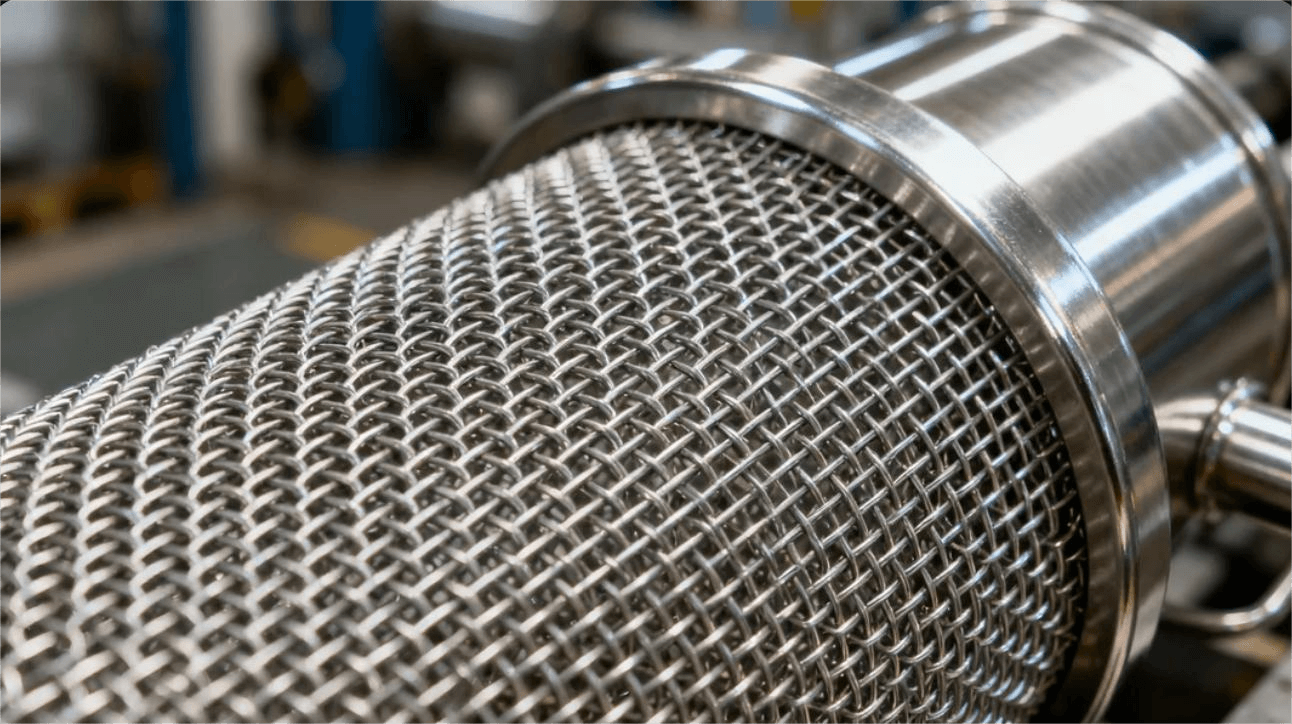

Woven wire mesh consists of interlaced wires forming a grid-like structure. The mesh can be made from various metals, including stainless steel, which is highly favored for its strength and resistance to corrosion.

Manufacturing Process

The manufacturing process involves weaving wires together in specific patterns, such as plain weave or twill weave. This process determines the mesh’s filtration characteristics and suitability for different applications.

—

Key Benefits of Woven Wire Mesh in Filtration

High Filtration Accuracy

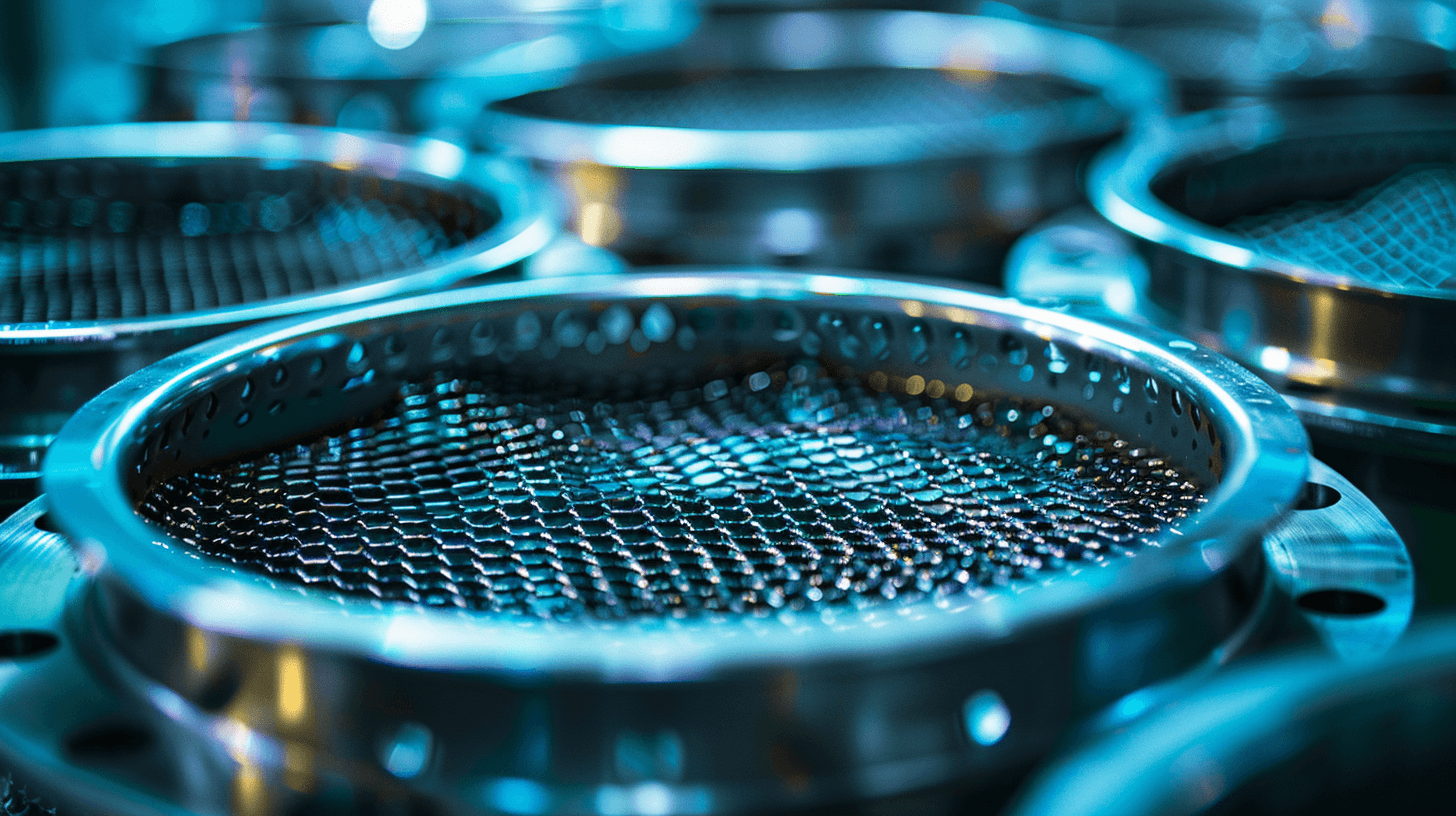

One of the primary benefits of woven wire mesh is its high filtration accuracy. The precise openings allow for effective separation of particles, ensuring clean and filtered outputs.

Durability and Strength

Woven wire mesh is renowned for its durability and strength. It can withstand high pressure and temperature conditions, making it ideal for demanding industrial environments.

Corrosion Resistance

Stainless steel woven wire mesh offers excellent corrosion resistance, which is crucial for applications involving exposure to chemicals and moisture.

—

Industrial Applications of Woven Wire Mesh

Chemical Industry

In the chemical industry, woven wire mesh is used for filtering and separating chemicals, ensuring purity and consistency in production processes.

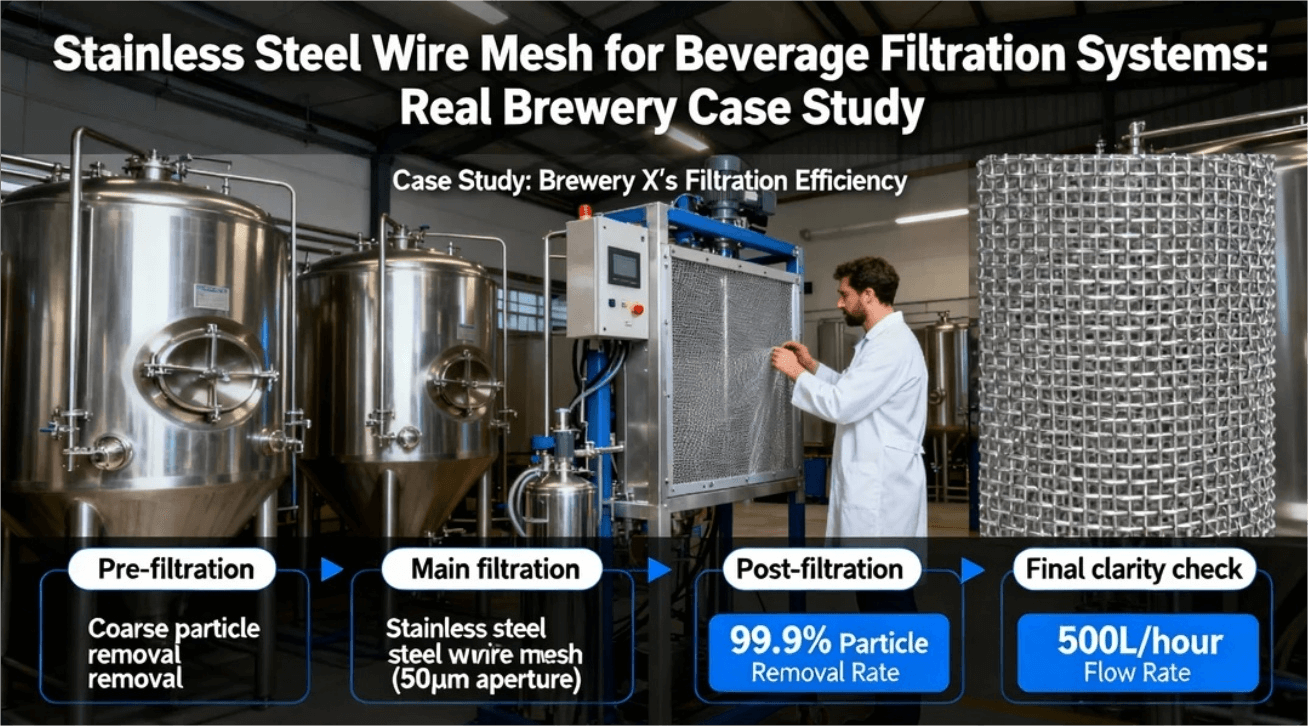

Food and Beverage Industry

The food and beverage industry relies on woven wire mesh for sieving and filtering ingredients, ensuring the quality and safety of the products.

Water Treatment

Woven wire mesh plays a critical role in water treatment plants, where it is used to filter out impurities and contaminants from water sources.

—

How to Choose the Right Woven Wire Mesh for Filtration

Mesh Count and Wire Diameter

When selecting woven wire mesh, consider the mesh count and wire diameter. Higher mesh counts offer finer filtration, while thicker wires provide greater strength.

Material Selection

Choose the appropriate material based on the specific needs of your application. Stainless steel is commonly used for its durability and corrosion resistance.

Weave Types

Different weave types, such as plain weave, twill weave and dutch weave wire mesh, offer unique filtration characteristics. Select the weave type that best suits your filtration requirements.

—

Conclusion

Woven wire mesh is a versatile and reliable solution for industrial filtration, offering high accuracy, durability, and resistance to corrosion. Understanding its benefits and applications can help you make informed decisions for your filtration needs. For more information on our woven wire mesh products and how they can benefit your operations, contact us today